Microbes are living organisms that cannot be seen with the naked eye because of their size.

Microorganisms are found in almost all environments and can be spread by direct human contact or by contact with contaminated surfaces (cross-contamination).

A shield to protect our environment

Natural Protective Shield (NPS) is the name of the technology developed and patented by Vestatis.

Through its application, surfaces of our habitats are permanently protected from the risk of microbiological contamination. The risk of indirect transmission of infectious agents from the contaminated surface to humans is thus minimised.

The invention, which is protected by an international patent application (PCT), is the result of the work of the Italian research team at Vestatis GmbH and has led to the development of a range of products dedicated to surface protection.

How it works

The basis of our invention is the discovery that the inclusion of a natural, botanically extracted molecule within a polymer matrix makes the treated surface self-sanitising, lowering its microbiological load.

This effect is based on the specific mechanical action of the molecule, which crystallises and spreads in the polymer matrix after application to the surface. A dense crystal structure is formed, which acts like a protective barrier and prevents adhesion and thus microbial colonisation.

This shield allows the surface "contamination" level to be maintained at near-zero levels permanently, with guaranteed results for 3 years.

NPS technology is completely non-toxic to humans and respectful of the environment.

Proven and measurable efficacy

The numerous tests carried out both in vitro and in vivo, i.e. in real contexts, have shown that this natural molecule exerts a very high power to reduce the microbial load, resulting fully effective against both Gram positive and Gram negative bacteria.

The effectiveness of NPS technology can also be easily measured with the bioluminometer, the use of which is recommended before and after product application.

Follow-up measurements can also confirm the continued effectiveness of the treatment in the following months.

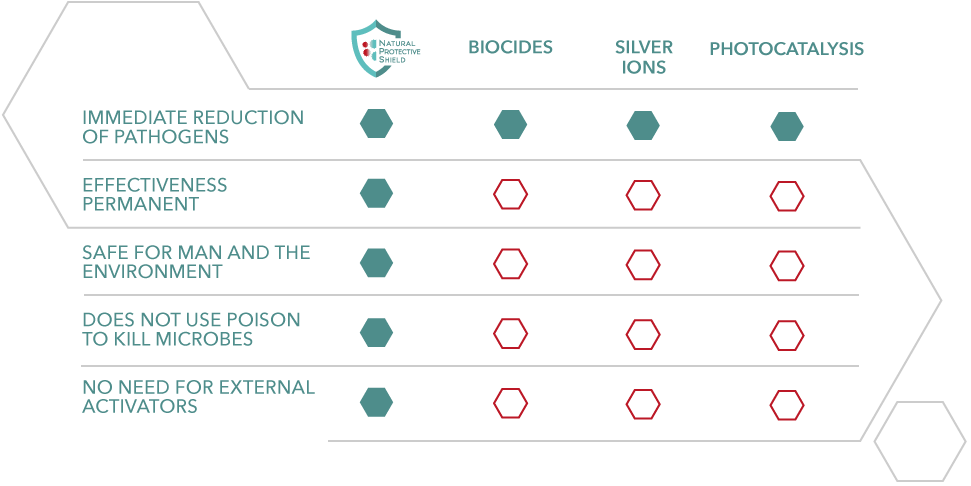

Comparison with other environmental biosafety techniques and products

Traditional surface disinfection methods base their effectiveness on the elimination of microorganisms such as bacteria, viruses and moulds through the action of chemicals.These methods have several disadvantages as they only have a short-term effect with little or no residual effect. Therefore, the surface is susceptible to re-contamination, which can occur immediately after a treatment.

Natural Protective Shield provides immediate pathogen reduction that lasts and protects 24/7 for at least 36 months.

The various biocides used to disinfect surfaces are gradually losing their effectiveness.Microorganisms develop resistance, which can reduce the effectiveness of those biocides (read more about this in our blog).The molecule of natural origin on which the NPS technology are based is harmless to humans and environmentally friendly. Moreover, it does not suffer any loss of efficacy due to its unique mechanical mechanism of action: Thanks to its ability to act like a "protective shield", the innovative NPS technology significantly reduces the risk of transmission of multi-resistant microorganisms.

In recent years, products have been introduced to the market that promise active protection against a microbial load based on biocides. In reality, however, the technologies behind these products are far less innovative than they promise and especially not compared to traditional methods.

Sanitisation based on silver ions, for example, can be applied using two different methods: nebulisation or inclusion in coating matrices.

Spraying poses the same problems as biocides, such as short duration of action, induction of resistance and toxicity to humans and the environment.

Silver coatings often have low efficacy because the ions with chemical antibacterial effect are almost completely enclosed in the coating matrix. The silver ions exposed on the surface can be gradually removed by the washing processes, so that the surface loses its antimicrobial effect.

Natural Protective Shield coatings are activated after application on the surface by forming a dense crystal network that does not allow microorganisms to adhere. Thanks to its crystalline form, the cell membranes of microorganisms already present are punctured and killed.

The main problem here is that light is required to activate the oxidative effect that underlies microbial inhibition: All areas that are not reached by light are not photoactivated and therefore remain unprotected. In the absence of light at night or in dark rooms, the technology does not work.

In addition, chemicals such as titanium dioxide are used to catalyse the reaction. These chemicals have the same toxicity problems as biocides, and as nanoparticles they are able to enter the body.

Treatment with Natural Protective Shield products does not require any external activator because the oxygen in the air itself triggers cross-linking.

Once the crystal mesh has formed, the surface constantly disinfects itself and does not need to be disinfected again for 36 months.

This also makes normal cleaning activities considerably easier, with a great economic advantage.